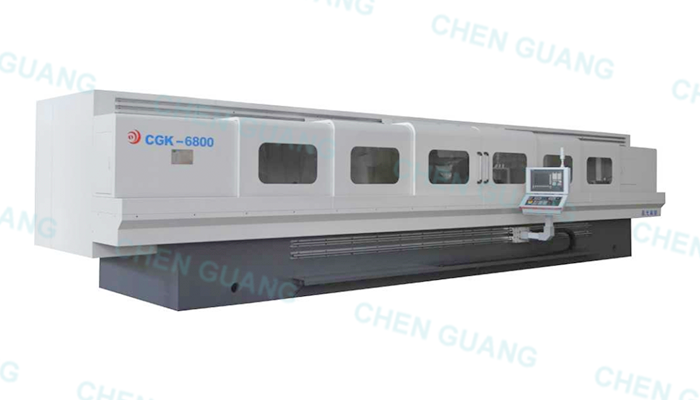

Application and characteristics of machine tool

1. Transmission mode and grinding thread length:

Cgk-4000 / 5000 / 6800 / 8500 (grinding thread length 4000 / 5000 / 6800 / 8500) uses grinding wheel carriage to move. It is attached behind the side bed. The grinding length is 14m (tool grinding).

2. Siemens 840D numerical control system, Heidenhain precision grating ruler and Renishaw encoder are adopted to realize full closed-loop control. The operation interface is Chinese man-machine dialogue interface, menu input, easy to operate.

3. The grinding mode adopts single line grinding cycle. It has the functions of full automatic cycle grinding, multi thread grinding, dynamic tool setting, pitch compensation, middle warp taper compensation and automatic compensation in grinding wheel dressing

4. The main bed and worktable are made of the original machine parts, and the guide surface is scraped and grinded with high precision. The mother screw and cross feed screw of the machine tool are made of domestic or imported high precision grinding ball screw to ensure the accuracy and stability of movement.

5. The grinding wheel spindle adopts imported high stiffness rolling bearing, which has high rotation accuracy, rigidity and wear resistance.

6. Adopt semi closed or fully closed protection. Equipped with standard full-length spray device, constant temperature forced cooling device, air purifier, magnetic filter, etc., the working environment is good.

7. Flexible configuration. The machine tool can be equipped with various wheel dressing devices, such as diamond roller shaping dresser, electric diamond pen dresser, CNC copying dresser, etc., and can be equipped with automatic balance device, automatic tool setting device, automatic screw angle adjustment locking device, centrifugal separator, etc.